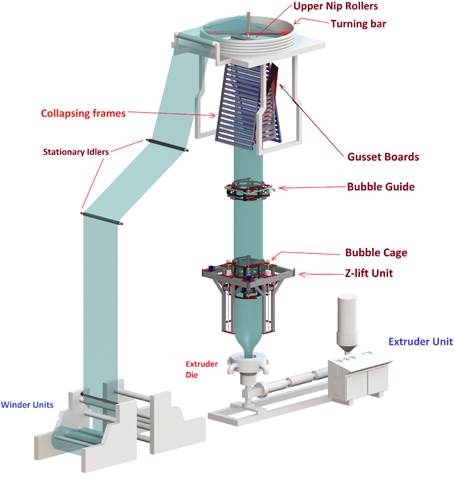

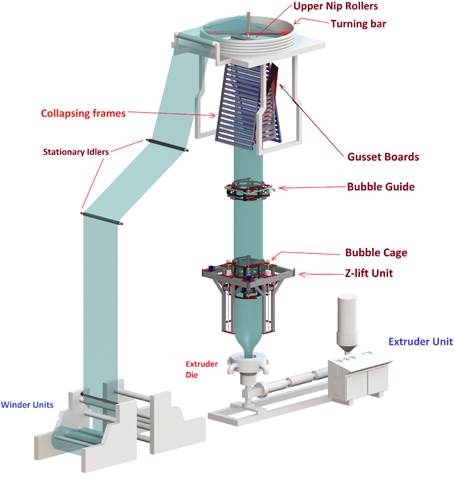

The process of blown film extrusion is a cornerstone technique for producing a wide array of flexible packaging materials. At the heart of this process lies a series of intricate equipment components, each playing a vital role in ensuring the quality and efficiency of the final product.

In this guide, we share insights into the mechanics of blown film extrusion, exploring key components such as bubble guide and arms, gusset board, collapsing tent and side guides, pre-nip and nip chillers, airless turning bars, non-turning idlers, and spreader bars. By understanding the functionality, benefits, and critical considerations of these components, manufacturers can optimize their extrusion processes, while mitigating potential risks associated with subpar equipment.

The Extrusion Process for Blown Film

Blown film extrusion is a versatile manufacturing process used to create plastic films of varying thickness and properties. It involves the continuous extrusion of liquid plastic through a circular die, forming a tube-like structure known as a bubble. As the bubble expands, air is introduced to inflate the tube to the desired diameter, while cooling systems aid in solidifying the material. The tube is then collapsed and flattened into a continuous sheet, which can be further processed or converted into various packaging products.

From the Bubble to the Film Roll

Once the bubble is formed, a series of interconnected components work in tandem to transform raw materials into finished film products. Here’s a breakdown of the key stages and components involved:

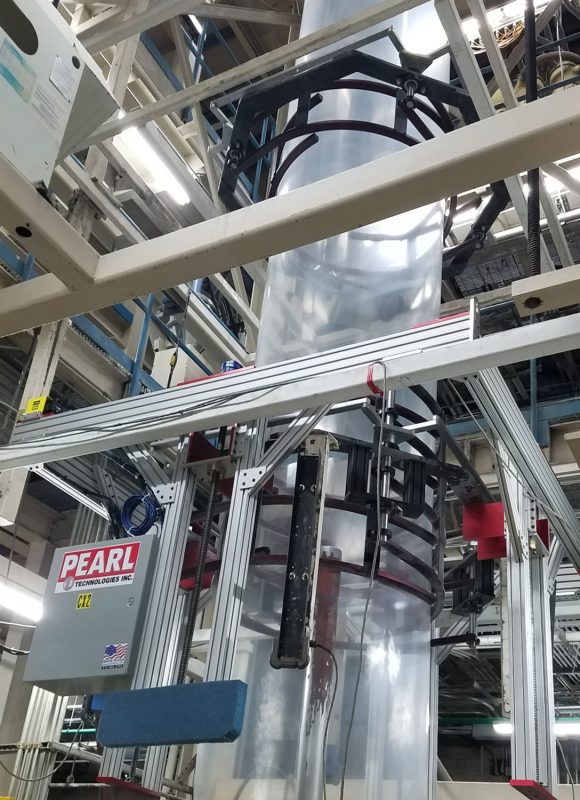

Z-lift Cages

Pearl’s Z-lift Cages enable quick setup and optimization of the extrusion process, contributing to enhanced productivity and efficiency. They ensure uniform film thickness across the width of the bubble, leading to improved product quality and consistency. By providing greater control over bubble cage positioning, these units also offer flexibility in accommodating variations in raw material properties or processing conditions.

Bubble Guides and Arms

These pieces of equipment are tasked with supporting and controlling the inflated bubble as it ascends through the extrusion line. Their main function is to ensure the uniform formation and stability of the bubble, thereby facilitating the production of consistent and high-quality film. Bubble guides direct the bubble’s ascent, while arms provide additional support and control, helping to prevent sagging or irregularities in the bubble shape.

The benefits of bubble guides and arms are multifaceted. As we mentioned, they contribute to the overall integrity and uniformity of the film by maintaining consistent bubble dimensions and thickness. But they also help to optimize the extrusion process by minimizing downtime and waste associated with bubble instability or misalignment. Their precise control over bubble formation also enables manufacturers to achieve tighter tolerances and greater control over product specifications.

Gusset Board

A gusset board facilitates the formation of gussets – folds or pleats – in the film. Its main function is to enhance the versatility and functionality of the film by providing additional volume and dimensional stability. During extrusion, the gusset board guides the film to create pleats along its edges, allowing the film to expand or contract as needed to accommodate variations in product dimensions or packaging requirements.

Gusset boards enable manufacturers to produce films with increased capacity and volume, making them suitable for applications requiring bulkier or larger packaging solutions.

Collapsing Tent and Side Guides

One of the most critical contact areas is the collapsing tent and side guides. Optimum film quality and output requires as little friction as possible while maintaining some friction for bubble stability. Collapsing tents and side guides work in tandem to facilitate the controlled collapse of the inflated bubble into a flat sheet. Their main function is to guide and support the bubble as it transitions from its expanded state to a flattened configuration, ensuring uniformity and consistency in the final film product. Collapsing tents enclose the top portion of the bubble, providing structural support and directing the flow of air to facilitate collapse, while side guides assist in maintaining proper alignment and tension along the edges of the film.

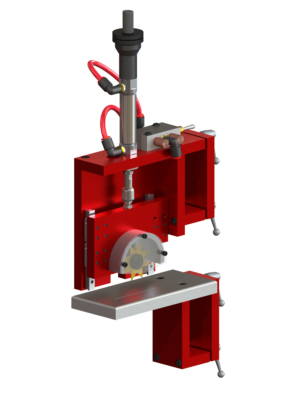

Pre-nip Chillers

This is the last critical contact area that is often unutilized prior to the nip rollers. Often times, film makers will add expensive additives to the film to achieve the results that a pre-nip chiller can achieve.

Pre-nip chillers cool the film as it passes through the nip rollers, thereby solidifying the material and enhancing dimensional stability. Their main function is to expedite the cooling process by dissipating heat from the freshly extruded film, preventing distortion or deformation, while improving overall product quality. This controlled cooling process helps to enhance surface quality and appearance, resulting in smoother, more uniform films with reduced surface defects.

Airless Turning Bars

Airless turning bars orient and align the film as it moves through the extrusion line without the use of air assistance. Unlike traditional turning bars that rely on air jets to manipulate the film, airless turning bars achieve similar results through mechanical means, providing greater flexibility and reliability in film handling.

Airless turning bars minimize the risk of film distortion or damage associated with air-assisted turning systems, particularly in applications where delicate or sensitive films are being processed. By eliminating the need for compressed air, airless turning bars reduce energy consumption and operating costs, while simplifying installation and maintenance requirements.

Non-Turning Idlers

Non-turning idlers are essential components in the blown film extrusion process, serving to provide support and guidance to the film as it travels through the extrusion line without imparting any rotational motion. Their main function is to maintain proper tension and alignment of the film, ensuring smooth and stable transport without introducing unwanted wrinkles or distortions. Unlike turning rollers or bars, which actively rotate to manipulate the film, non-turning idlers remain stationary and simply support the film as it passes over or around them.

These pieces of equipment help to minimize friction and wear on the film surface by providing low-resistance support, reducing the risk of damage or marking during transport. By maintaining consistent tension and alignment, non-turning idlers contribute to the overall integrity and uniformity of the film, resulting in a smoother, more uniform product with fewer defects. Additionally, non-turning idlers offer simplicity and reliability in operation, requiring minimal maintenance and adjustment compared to more complex turning systems.

Spreader Bars

Spreader bars, or bowed “D” rollers, evenly distribute tension across the width of the film as it progresses through the production line. Their main function is to prevent uneven stretching or distortion of the film, ensuring uniformity and consistency in thickness and appearance. Spreader bars achieve this by applying controlled pressure to the center of the film, effectively widening it by spreading the film across the bow, and minimizing the risk of wrinkles or creases. This leads to fewer defects and higher overall product yield. Spreader bars are also an easy way to achieve line separation without introducing wrinkles to the web as multiple rolls are formed.

Why Choose a Solutions Provider Like Pearl for Extrusion Equipment Needs

As a leading provider of extrusion solutions, Pearl understands the critical role that quality equipment plays in optimizing the blown film extrusion process. With a commitment to innovation, reliability, and customer satisfaction, Pearl offers a comprehensive range of state-of-the-art equipment and support services tailored to meet the diverse needs of manufacturers. By partnering with Pearl, manufacturers can benefit from:

- Cutting-edge technology and engineering expertise

- Customized solutions designed for maximum efficiency and performance

- Ongoing technical support and maintenance services

- Assurance of product quality, reliability, and compliance

- A long-term partnership focused on driving continuous improvement and success

- Access to our application lab for CoF testing to determine which wear-cover or wear-coating is ideal for your operation.