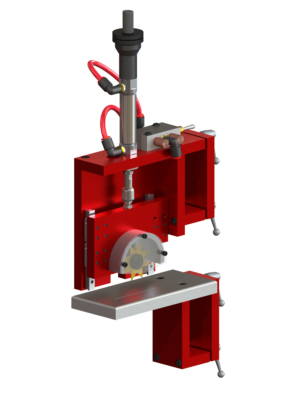

Rotary Perf Units for Industrial Perforation

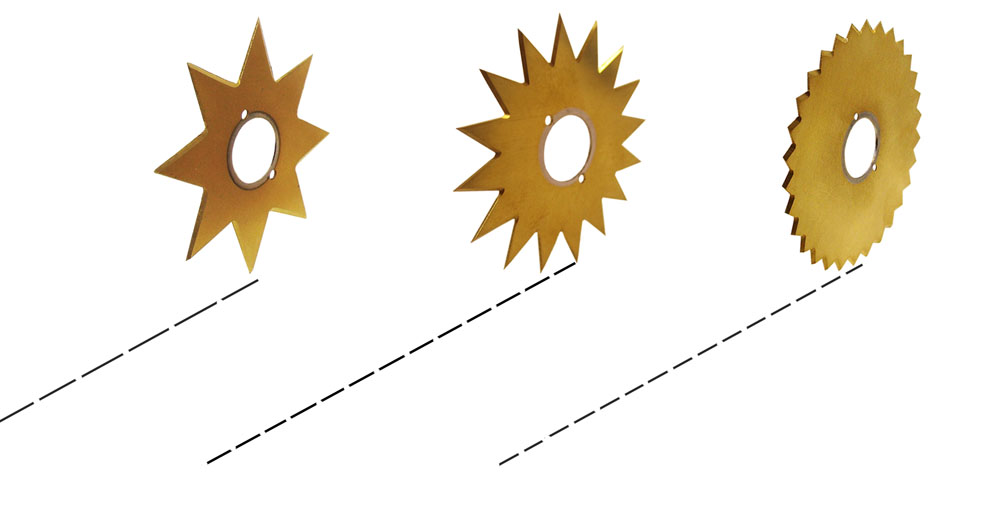

Film Driven with the Unique Ability to Vary the Depth of the Blade

Our cutting-edge rotary perforating units are designed meet the demands of high-volume bag manufacturing and industrial perforation needs. Our rotary perf units are engineered for precision, speed, and flexibility, making them the ideal choice for manufacturers looking to enhance their perforation capabilities. Whether you’re running long production cycles or need quick adjustments for short runs, Pearl has the perfect solution for you.

Why Choose Pearl’s Rotary Perf Units?

When it comes to industrial perforation, reliability, ease of use, and durability are key. Our rotary perf units are trusted by industry leaders worldwide for their superior performance, minimal maintenance requirements, and ability to handle FDA-approved materials. Whether you’re producing food packaging, medical bags, or other industrial products, Pearl offers a perforation system tailored to your needs.