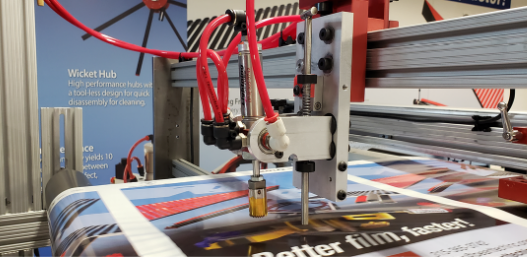

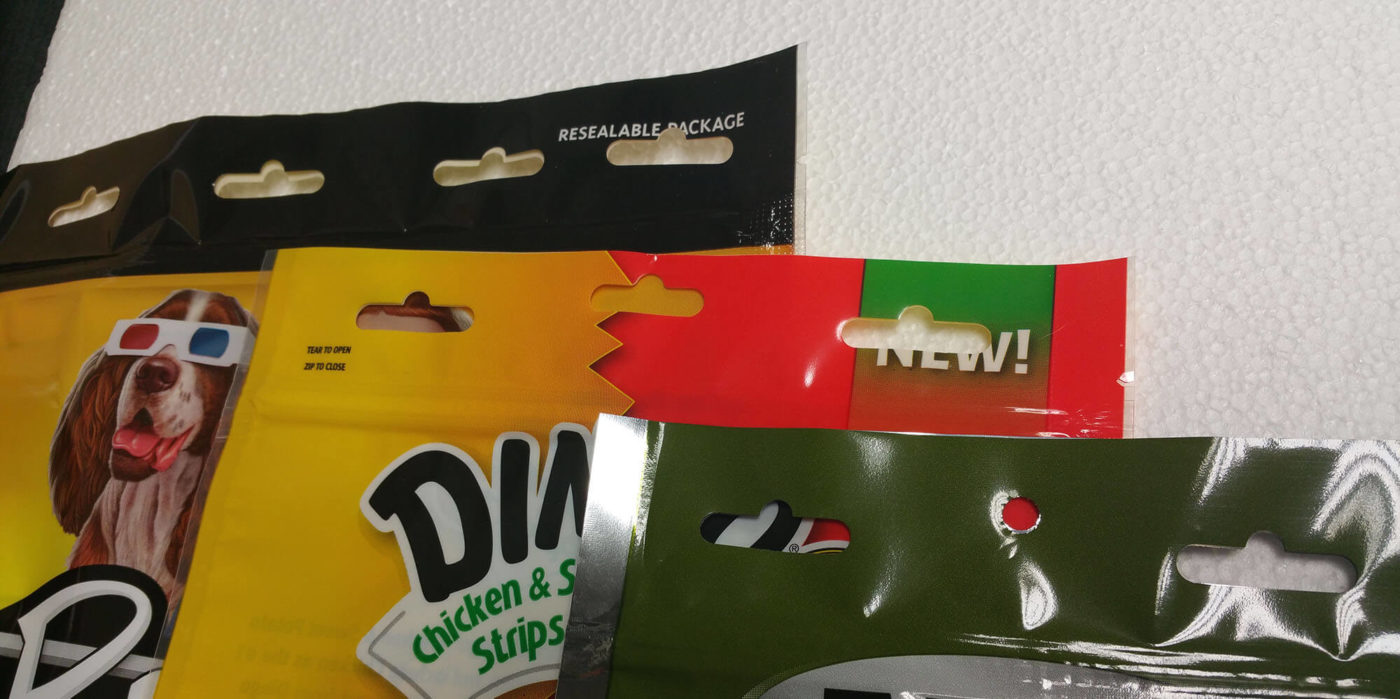

Fast, clean, and consistent cutting of pouch packaging material or blown plastic film is only possible with exactly the right punch and die clearance for your application. While many cut-rate suppliers may save you money upfront, a reputable technology partner will work with you to identify the best combination of punch unit, punch attachment, and […]

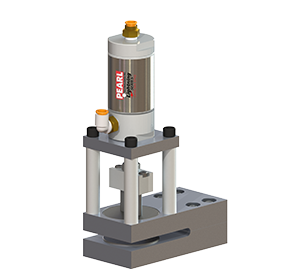

Savannah, New York (October 3, 2022) – Pearl Technologies today announced the introduction of its “Value” range of Zero Clearance (ZC) punching units. The new range of “disposable” units provide excellent punch quality at budget-friendly pricing for punching round holes, hanger holes, corner rounds and tear notches. The Value ZC units are part of Pearl’s […]

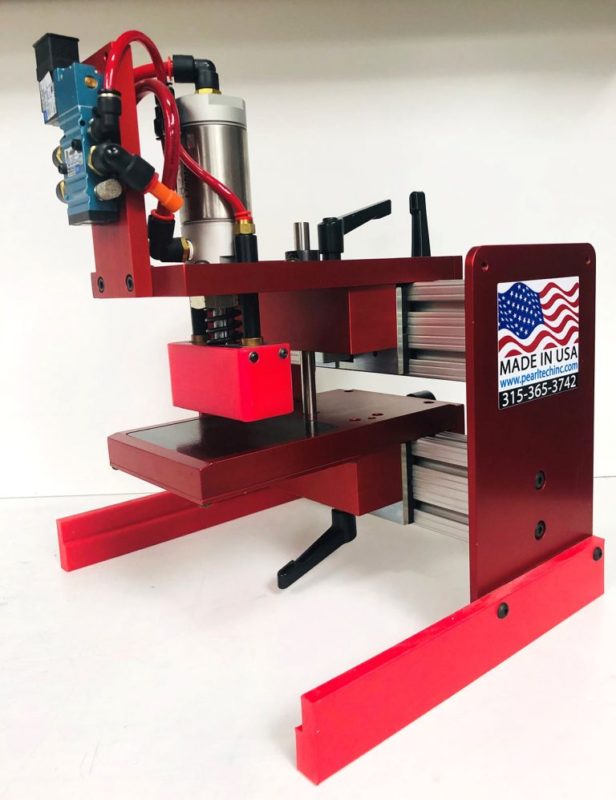

If you are investing in a plastic packaging operation or expanding an existing operation, you’ll need to look at punching machinery, but how much does a new punching machine cost? Making the Cut: Estimating Punching Machines Costs Depending on your flexible packaging processing or converting application, your punching machine is either the final touch to […]

Cheap punching machinery might get your flexible packaging product out the door but poor quality punching can cost you more in the long run. Poor Quality Punching Machinery Can Hit You Where It Hurts Nothing takes away from the quality of your flexible packaging like shoddy hole punching and placement. Failing to invest in quality […]

Addex has partnered with Pearl Technologies to create robust, “smart” bubble cage that will debut at K 2022 in Dusseldorf, Germany. The cage features Addex’s proprietary 100% pure digital automatic controls. The Addex + Pearl Digital Bubble Cage provides smooth, consistent bubble-diam control and features Pearl’s unique patented cage arm technology. To learn more, click here!

All flexible packaging punches are not created equal. Pearl Technologies’ performance packaging punches offer significant advantages in durability, customizability, and performance over the superior quality you already expect from our industry-leading standard products. Let’s take a look at how Pearl’s performance punches offer added value to your operation across a wide range of applications. Guaranteed […]

Toothed and die cut punches offer distinct cutting solutions for different plastic packaging materials. Deciding whether to invest in the precision of a die cut punching or opting for the flexibility and cost-effectiveness of toothed punch technology depends on the type and thickness of film you are cutting. Getting the Edge: Toothed vs. Die Cut […]

Savannah, New York (August 8, 2022) – Pearl Technologies today announced that Tom Crawford has been hired in the newly created position of Sales Director, at the leading manufacturer of punching and handling solutions for plastic film. In this position, Mr. Crawford will develop and manage a strategic sales plan that will help grow successful […]

We offer a range of hole types: tear notch, hanger hole, handle hole, and vent holes. Our products can adapt to changing market demands, as we built our products with sustainability and versatility in mind. From seal to slit to hole, we have a full line solution. Are two of our most popular units are […]

Savannah, New York (April 12, 2022) – Pearl Technologies today announced that Rocco Panetta has been hired in a newly created position of Technical Sales Manager – Pouch, at the leading manufacturer of punching and handling solutions for plastic film. In this position, Mr. Panetta will develop and manage a network of customers focused on […]