Savannah, New York – March 31, 2017 – Pearl Technologies just unveiled several new packaging products aimed at increasing converter line safety. These products not only deliver higher productivity and lower cost of ownership, but also address the growing need to increase safety in today’s high volume converter lines.

“We constantly talk to our customers and one of the things we hear repeatedly is the need to increase the safety of converter production lines,” said Laurent Cros, CEO of Pearl Technologies.

“Pearl manufactures some of the sharpest punches and cutters in the industry, so we took it upon ourselves to re-design some of our products to not only keep production lines operating at peak efficiency, but also provide a safer work environment for the production teams,” Cros shared. “For example, the new safety enclosure on our lightning wicket punch eliminates exposure to the sharp punch teeth from the time the cutter is received, stocked, transferred within the facility, installed into the unit and removed at time of disposition. The enclosure eliminates any chance of accidental cuts to workers who handle the unit.”

Pearl designed the Lighting Wicket Punch Safety Enclosure, which guarantees zero cuts when handling, installing or removing the punch. Teeth are never exposed outside of the attachment so there is no way to drop, hit or damage the teeth while installing.

Installation is still easy and saves a great deal of time during changeovers, seconds instead of minutes. Additionally, the box is transparent, allowing operators to see the color coding of the body, which defines the punch gap to slit specifications.

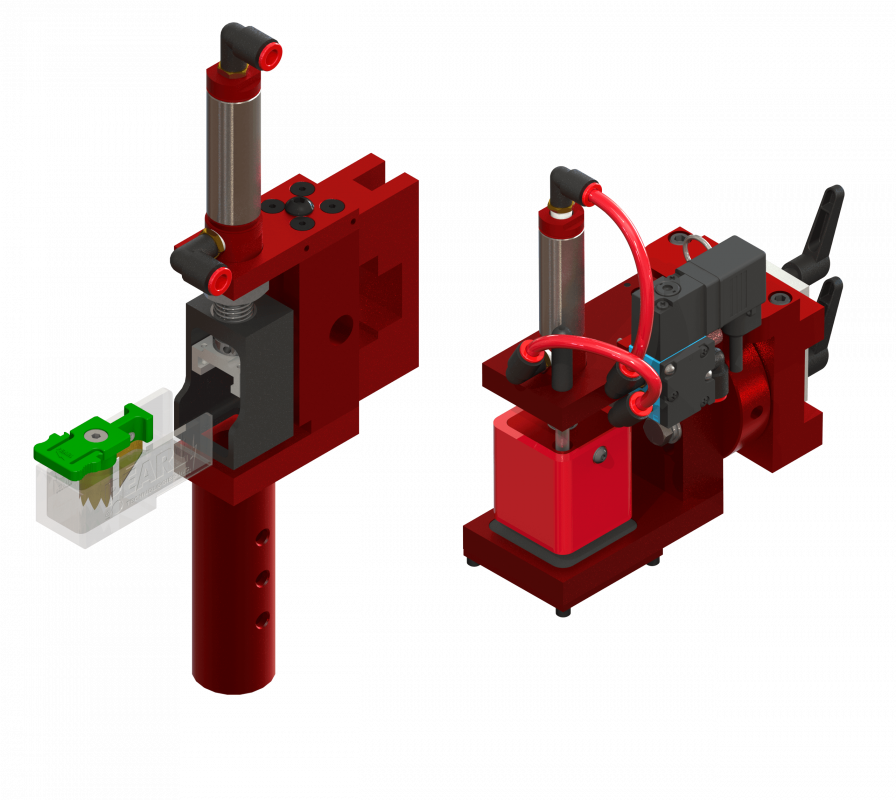

The innovative Pivot Mount Assembly for our Flex Units allows operators to rotate the unit 180 degrees for easier access to the die plate, screws and punch. When doing changeovers, this gives the operator improved visibility and increased efficiency.

Just rotate the unit in 90-degree increments with the easy-to-use location pin to gain easy access to the punch within. Like all Pearl’s Flex Units, various punch profiles and sizes are available. This still allows customers to use one machine with multiple punching profiles and patterns. The Pivot Mount Assembly is available on Flex 1, 2, 3, and 4 Units.

Pearl’s rendition of bowed rollers just got even better with the creation of the Remote Control Spreader Bar. This new capability allows operators to quickly change the bow’s operating parameters in hard to reach locations such as tight or high up places, or across wide webs.

Like all of Pearl’s other Spreader Bars, the remote controlled unit still aids with wrinkle-prevention and lane separation. Spreaders can be coated with the new SM28 coating, even better than SM24, or covered with one of Pearl’s Low Coefficient of Friction slats.

This is only just the start of Pearl’s re-designs. Pearl will be revealing various enhancements to other customer-favorite products throughout the year. Visit www.pearltechinc.comto stay up to date.

Links:

Lightning Wicket Punch Safety Enclosure:

Pivot Mount Assembly for Flex Units:

Remote Control Spreader Bar: